Nanotechnological Devices

Molecular shuttles are envisioned as potential workhorses of future nanotechnological devices. They can easily be tracked by fluorescence microscopy, guided on surfaces and functionalized with a broad range of cargo. Therefore, applications like biosensing devices, molecular assembly lines in a lab on a chip, surface imaging and single-molecule manipulation are envisioned or have partially been realized for this molecular transport system.

Cargo pick up and unload in an integrated device

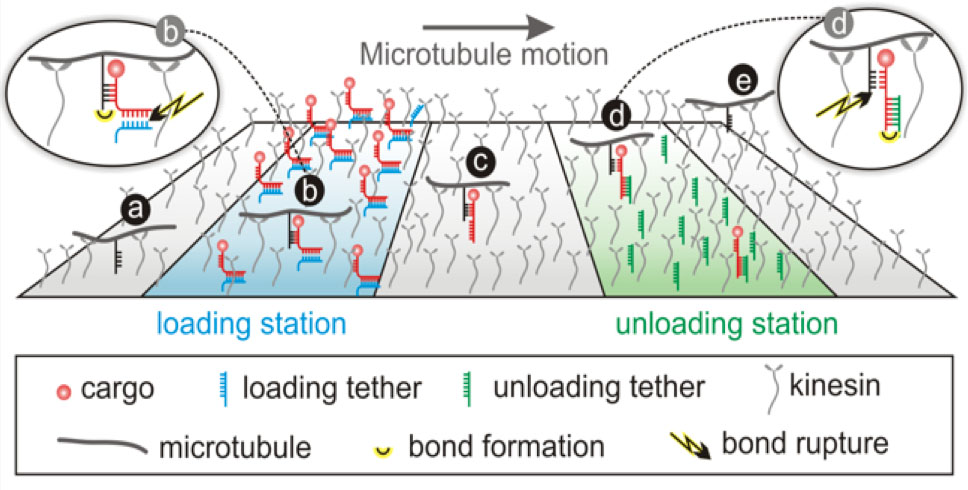

A central challenge in engineering biohybrid devices powered by motor proteins is the assembly of a transport system that is capable of picking up cargo in one location and delivering it to a target destination while achieving high spatial and temporal control. We have designed such a nanoscale device, by implementing the following requirements: Integrating cargo loading and unloading stations into a single platform, and adjusting the cargo linker chemistry to achieve facile cargo pick up and unload (Figure 2).

Figure 2 Cargo translocation by molecular shuttles.

A) A microtubule functionalized with single stranded DNA enters the loading station where DNA labeled cargo is immobilized in zipping geometry.

B) Cargo binds to the microtubule in shearing geometry. As the microtubule moves on, the mechanically weaker zipping bond between the cargo and loading station ruptures and the cargo is transferred to the microtubule.

C) Cargo is transported to the unloading station.

D) Cargo attaches to the unloading station in shearing geometry. As the microtubule continues to move the mechanically weaker bond between the cargo and the microtubule ruptures and the cargo is deposited in the unloading station.

E) The microtubule moves on to its next cargo translocation cycle.

Figure from external pageSchmidt et al. 2010call_made

Cargo loading and unloading stations

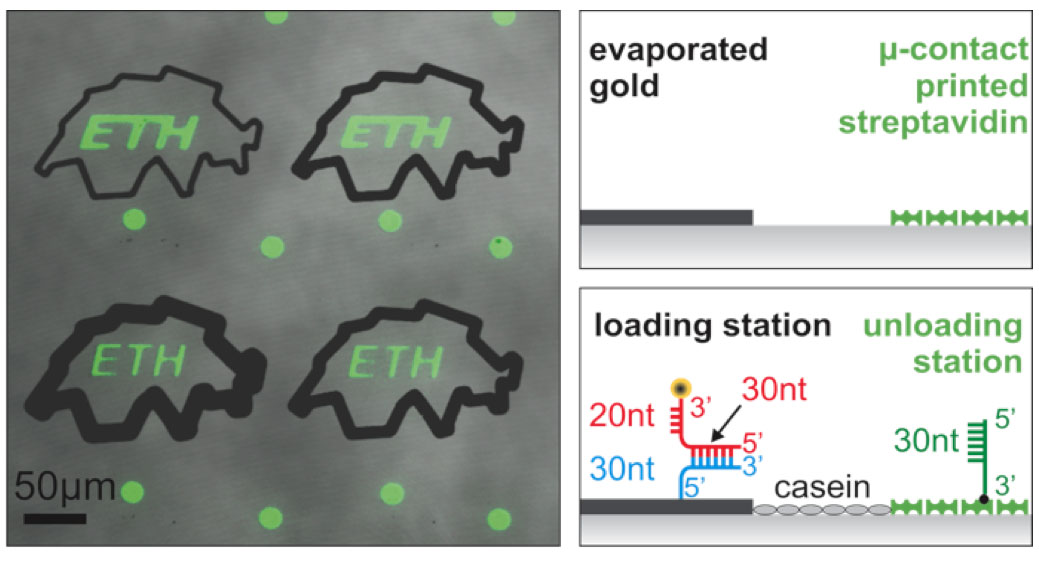

Cargo loading and unloading stations were prepared utilizing microfabrication techniques (Figure 3). DNA was chosen to link cargo to both stations and the microtubule. By using the same DNA sequence hybridized in different geometries (zipping vs. shearing), we could tune the forces required to separate cargo from the loading station and transfer it to a passing microtubule and to detach cargo from the microtubule to deliver it at the unloading station. A complete transport process of cargo pick up, transfer, and delivery was demonstrated in a proof of concept experiment (Movie 2). Our system could be utilized as an integral component in future lab on a chip applications, enabling sorting or assembly of nanostructures.

Figure 3 Microscopy image of loading and unloading stations integrated on one surface. Loading stations have the shape of a map of Switzerland while unloading stations resemble the ETH logo. Right: Schematic illustrating the structure of the surface patterns: gold lines are prepared by photolithography, gold evaporation and photoresist lift-off; Streptavidin patterns are fabricated by µ-contact printing of Streptavidin. Loading stations are assembled by attaching sulfhydryl-modified DNA to the gold lines, followed by DNA labeled gold colloids. Unloading stations are prepared by adding biotin-modified DNA to the Streptavidin areas. Figure from external pageSchmidt et al. 2010call_made.